This content requires cookies, please click 'Allow Cookies' at the bottom of the screen.

Keeping temperatures low at high speed: BASF and RML – Material expertise and know-how come together for innovative e-mobility technologies.

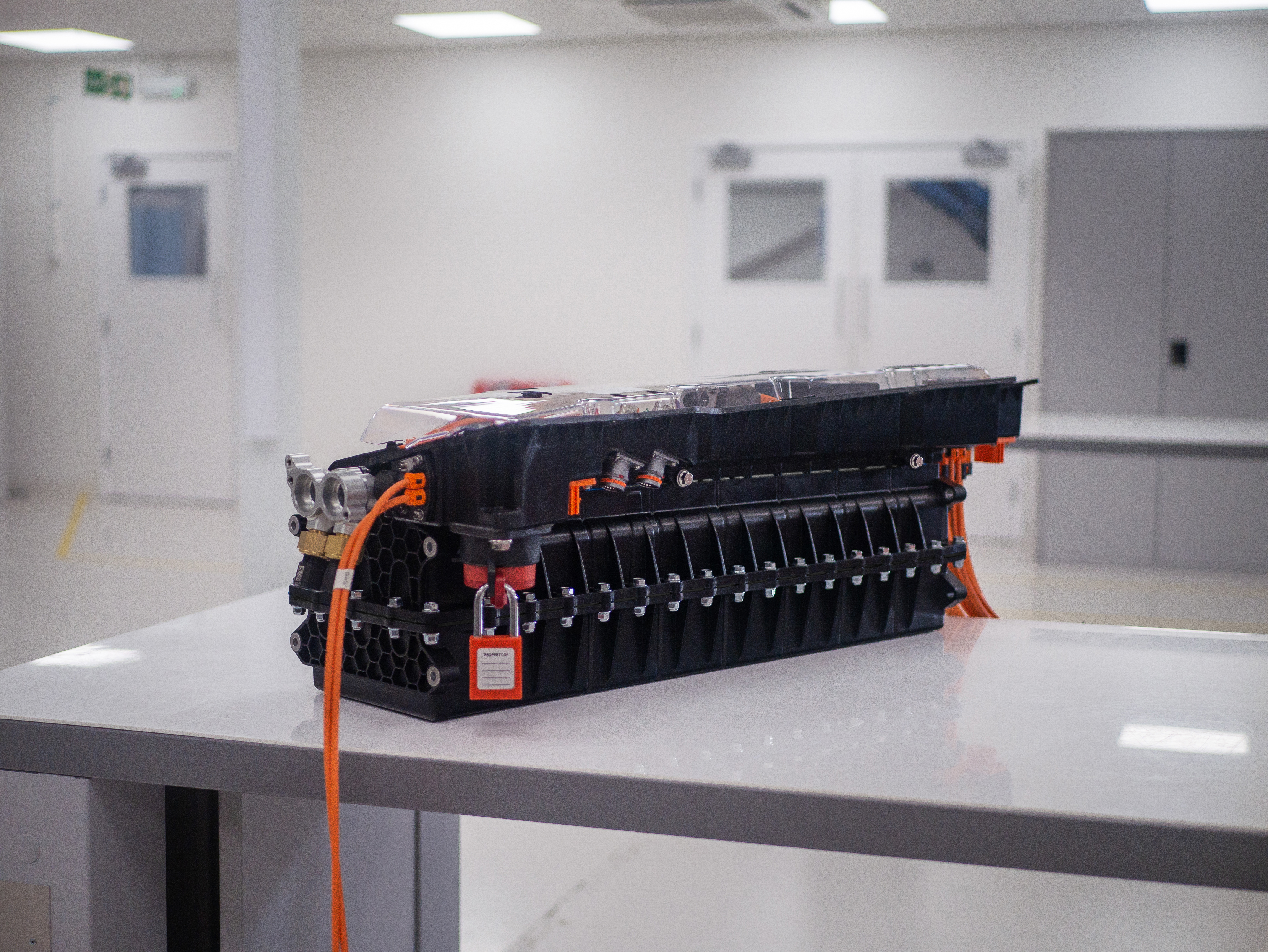

- BASF's Ultramid® B3EG7 and Ultramid® A3EG6 EQ are used by RML as housing material and cell holders in the battery unit.

- Immersion cooling improves the battery system’s efficiency and service life.

- Accelerated development thanks to in-depth materials expertise and service offerings.

BASF, the world's leading provider of materials solutions in the plastics sector, has supported RML Group in the development of an innovative, immersion-cooled battery for a high-performance hybrid hypercar that sets new performance and safety standards using next-generation plastic materials. The 800V battery features a capacity of 4.2 kWh and a discharge rate of >100C, weighing in at less than 75kg.

The extremely high-power output, especially during rapid acceleration and regeneration, requires a cooling system capable of rejecting the heat generated by the cells. To prevent extreme temperatures and ensure a more even temperature distribution throughout the pack, immersion cooling is used, which greatly improves the entire battery system’s efficiency and service life. Two BASF plastics are used in RML's battery unit.

First, there is Ultramid® B3EG7 (PA6GF35) both as the housing material for the battery unit itself and in the housing of the high-voltage electrical components of the battery control system. This plastic is noted for its robustness and high resistance to mechanical stressing, which is particularly important for the battery housing. The design not only has to satisfy crash requirements, but also must pass the UNCE Reg 100.03 fuel fire test. Protected only by a thin carbon sheet integrated into the test as a body part, Ultramid® B3EG7 passes the fire test without damage to the housing, making it ideal for this application.

Second, Ultramid® A3EG6 EQ (PA66GF30) is used as the material for the individual battery cell holders within the battery housing. The Ultramid® EQ grades (EQ = Electronic Quality) are extremely pure-grade, i.e. they contain hardly any electrically active or corrosion-promoting contents and still deliver outstanding heat aging resistance. In contact with the dielectric fluid, the material minimizes any kind of diffusion out of the material. Since dielectric fluids are used for electrical insulation and as coolants in high-voltage applications, contamination by contact materials must be avoided at all costs.

A strong partnership

The RML name is synonymous for superlative engineering achievements in the field of luxury and racing cars. The company is also a pioneer in the electrification of the automotive fleet through its development, design and production of novel and highly innovative battery systems. Particularly noteworthy is the close cooperation between BASF and RML even at the development stage and the early involvement of BASF as a materials supplier in decision-making processes.

“RML needed to explore state-of-the-art materials for battery systems to meet the mass and structural targets set by customers for high-performance applications. We worked closely in collaboration with BASF to achieve the desired properties and I look forward to working together evolving and enhancing material development with BASF on future projects.” expresses James Arkell, Head of Powertrain at RML.

Thanks to its extensive expertise in the new battery sector and in the field of electrical and electronic (E/E) materials, BASF managed to significantly accelerate the development of the overall battery unit. The rapid recommendation of suitable materials as well as the timely, global delivery of sample quantities were instrumental in ensuring that RML was able to meet its ambitious schedule for this project. BASF’s agile approach underscores its commitment to providing groundbreaking solutions that meet the evolving needs of the automotive industry.

"Our in-depth materials expertise and commitment to sustainable solutions enable us to meet customer requirements in the shortest possible time and advance electrification in the transport sector," says Jasmina Simon, plastics materials expert for eMobility.

In addition to its materials solutions, BASF also provides comprehensive services such as component simulation. Ultrasim®, for example, can be used to develop components for specific requirements, so as to create heavy-duty, efficient and lightweight customized components.

BASF drives innovation in the automotive sector, providing sustainable and future-oriented solutions in plastics that are revolutionizing the way we power vehicles.

About BASF’s Performance Materials division

BASF’s Performance Materials division is at the forefront of the much-needed sustainability transformation in plastics. Our products are co-created with customers around the globe to bring innovations to four major industry sectors – transportation, consumer goods, industrial applications, and construction. Our R&D focuses on all stages of the plastics journey: Make, Use and Recycle. The MAKE phase is about improving how plastics are made, from product design to the choice of raw materials and the manufacturing process itself. The USE phase enhances plastics’ strengths such as light weight, robustness, and thermal resistance. At the end of the product lifecycle, the RECYCLE phase looks at how to close the loop to achieve a circular economy. In 2022, the Performance Materials division achieved global sales of €8.5 billion. Join #ourplasticsjourney at: www.plastics.basf.com

About RML Group

At RML, we specialise in crafting high-performance car derivatives and pioneering advanced automotive technology for OEMs. Our expertise extends to building prototypes, crafting show cars, and reviving historic road and racing vehicles. There is no boundary to our capabilities, we thrive on turning ambitious visions into reality. Whether it’s pushing limits of performance to preserving automotive heritage, RML stands at the forefront, ready to exceed expectations and redefine possibilities in the automotive world. www.rmlgroup.com

About RML Group Powertrain division

RML’s battery design, development and manufacturing capabilities have grown significantly in the past decade, first used in the development of the Nissan ZEOD RC Le Mans Garage 56 car and onto projects such as record-breaking EV supercars in the automotive sector. RML’s powertrain facility includes a 10,000 sq.ft manufacturing facility for battery systems and bespoke engine builds for RML’s internal combustion engine projects. This is combined with in-house cell characterisation capability and end-of-line equipment to compliment the battery manufacturing process. The Powertrain division’s expertise includes both high-power and high-energy battery systems, providing leading-edge technology in electrification for world-class automotive and off-highway applications. We’ve designed, developed, and built some of the world’s highest-performing and most efficient BEV, Hybrid and internal combustion powertrains, breaking multiple records and winning several awards for technology and innovation. We specialise in applying motorsport culture and design philosophies to tackle the challenges with emerging technologies and provide rapid development for our partners.